Available for pickup

Usually ready in 2 hours

Available for pickup

Usually ready in 2 hours

Unit 1, 3-7 Frankland Street

Mittagong NSW 2575

Australia

+61248799750

Out of stock

Usually ready in 2 hours

Unit 7, 3-7 Frankland Street

Mittagong NSW 2575

Australia

+61248799750

Components

EC Centrifugal Fan

This is the inline fan motor. Depending on its orientation, it can either extract stale air or supply fresh air. To reduce noise and protect the structure, the fan is suspended on durable hanging straps, preventing vibration from transferring into the building. The fan housing is proudly moulded in Australia to meet local quality and compliance standards, while the high-performance German-made motor delivers reliable, quiet operation and long-term efficiency.

Variable Speed

This controller uses a 0 – 10V potentiometer to provide infinitely variable speed control on our EC centrifugal fans. Unlike fixed or stepped controls, fan speed is adjusted smoothly and continuously across the full operating range. Even the smallest movement of the dial results in a precise change in airflow, allowing the fan speed to be set exactly where required — not limited to preset levels. This enables fine tuning for noise, airflow, and energy efficiency to suit each installation.

3-Pin Australian Plug and Lead

All of our centrifugal fans are supplied with a 3-pin Australian plug and lead, including a safety earth. While our fans are independently tested and certified for Australian electrical safety compliance and carry the Regulatory Compliance Mark (RCM), each individual unit is also tested and tagged at the time of dispatch to ensure it is safe and in full working order on arrival.

R3G190 Motor Specifications

Available in 150mm and 200mm Fan Housings

Specifications

The R3G190 EC motor from ebm-papst Germany is used in our 150mm and 200mm centrifugal inline fan range. Drawing on ebm-papst’s internationally recognised expertise in advanced motor technology, the R3G190 delivers outstanding efficiency, precise control, and long-term reliability for residential and light commercial ventilation applications.

As an electronically commutated (EC) motor, the R3G190 provides fully variable speed control, allowing airflow to be accurately matched to the specific requirements of the installation. Noise performance is another key advantage of EC motor technology. The R3G190 is inherently quiet, and when operated at reduced speeds, noise levels drop dramatically — making the fan exceptionally quiet in real-world use. For important context on why decibel ratings can be misleading when comparing fans, please refer to the FAQ section below.

Key specifications and features of the R3G190 EC motor include:

• Approximate airflow of 735 m³/h at 100% speed

• Power consumption of 83 W at 100% speed

• Fully variable speed control via 0–10 V potentiometer and EC motor technology

• Breakout sound pressure level of approximately 45–48 dB(A) at 100% speed

• Breakout sound pressure level of approximately 25–27 dB(A) at 30% speed

• IP54 protection rating

• 5-year warranty for long-term peace of mind

Each R3G190 EC motor is installed in a custom Australian-made centrifugal fan housing designed to support consistent airflow, minimise vibration, and protect the motor in demanding local conditions. The motor and fan assembly is independently tested, certified for Australian electrical safety compliance, and carries the Regulatory Compliance Mark (RCM).

150mm Centrifugal Fan

200mm Centrifugal Fan

100% Speed (10V)

- Maximum Absorbed Power: 83W.

- Maximum Delivery: 735 m³/h.

- Pressure Max: 825 Pa.

- RPM: 3,530.

80% Speed (8V)

- Maximum Absorbed Power: 49W.

- Maximum Delivery: 580 m³/h.

- Pressure Max: 369 Pa.

- RPM: 2,800.

60% Speed (6V)

- Maximum Absorbed Power: 24W.

- Maximum Delivery: 445 m³/h.

- Pressure Max: 218 Pa.

- RPM: 2,150.

40% Speed (4V)

- Maximum Absorbed Power: 10W.

- Maximum Delivery: 310 m³/h.

- Pressure Max: 105 Pa.

- RPM: 1,500.

R3G225 Motor Specifications

Available in 250mm and 300mm Fan Housings

Specifications

The R3G225 EC motor from ebm-papst Germany is used in our 250mm and 300mm centrifugal inline fan range. Drawing on ebm-papst’s internationally recognised expertise in advanced motor technology, the R3G225 delivers outstanding efficiency, precise control, and long-term reliability for residential and commercial ventilation applications.

As an electronically commutated (EC) motor, the R3G225 provides fully variable speed control, allowing airflow to be accurately matched to the specific requirements of the installation. Noise performance is another key advantage of EC motor technology. The R3G225 is inherently quiet, and when operated at reduced speeds, noise levels drop dramatically — making the fan exceptionally quiet in real-world use. For important context on why decibel ratings can be misleading when comparing fans, please refer to the FAQ section below.

Key specifications and features of the R3G225 EC motor include:

• Approximate airflow of 1,310 m³/h at 100% speed

• Power consumption of 147 W at 100% speed

• Fully variable speed control via 0–10 V potentiometer and EC motor technology

• Breakout sound pressure level of approximately 41–45 dB(A) at 100% speed

• Breakout sound pressure level of approximately 35–38 dB(A) at 30% speed

• IP54 protection rating

• 5-year warranty for long-term peace of mind

Each R3G225 EC motor is installed in a custom Australian-made centrifugal fan housing designed to support consistent airflow, minimise vibration, and protect the motor in demanding local conditions. The motor and fan assembly is independently tested, certified for Australian electrical safety compliance, and carries the Regulatory Compliance Mark (RCM).

250mm Centrifugal Fan

300mm Centrifugal Fan

100% Speed (10V)

- Maximum Absorbed Power: 147W.

- Maximum Delivery: 1,310 m³/h.

- Pressure Max: 718 Pa.

- RPM: 2,965.

80% Speed (8V)

- Maximum Absorbed Power: 111W.

- Maximum Delivery: 1,190 m³/h.

- Pressure Max: 508 Pa.

- RPM: 2,700.

60% Speed (6V)

- Maximum Absorbed Power: 60W.

- Maximum Delivery: 970 m³/h.

- Pressure Max: 340 Pa.

- RPM: 2,200.

40% Speed (4V)

- Maximum Absorbed Power: 28W.

- Maximum Delivery: 750 m³/h.

- Pressure Max: 200 Pa.

- RPM: 1,700.

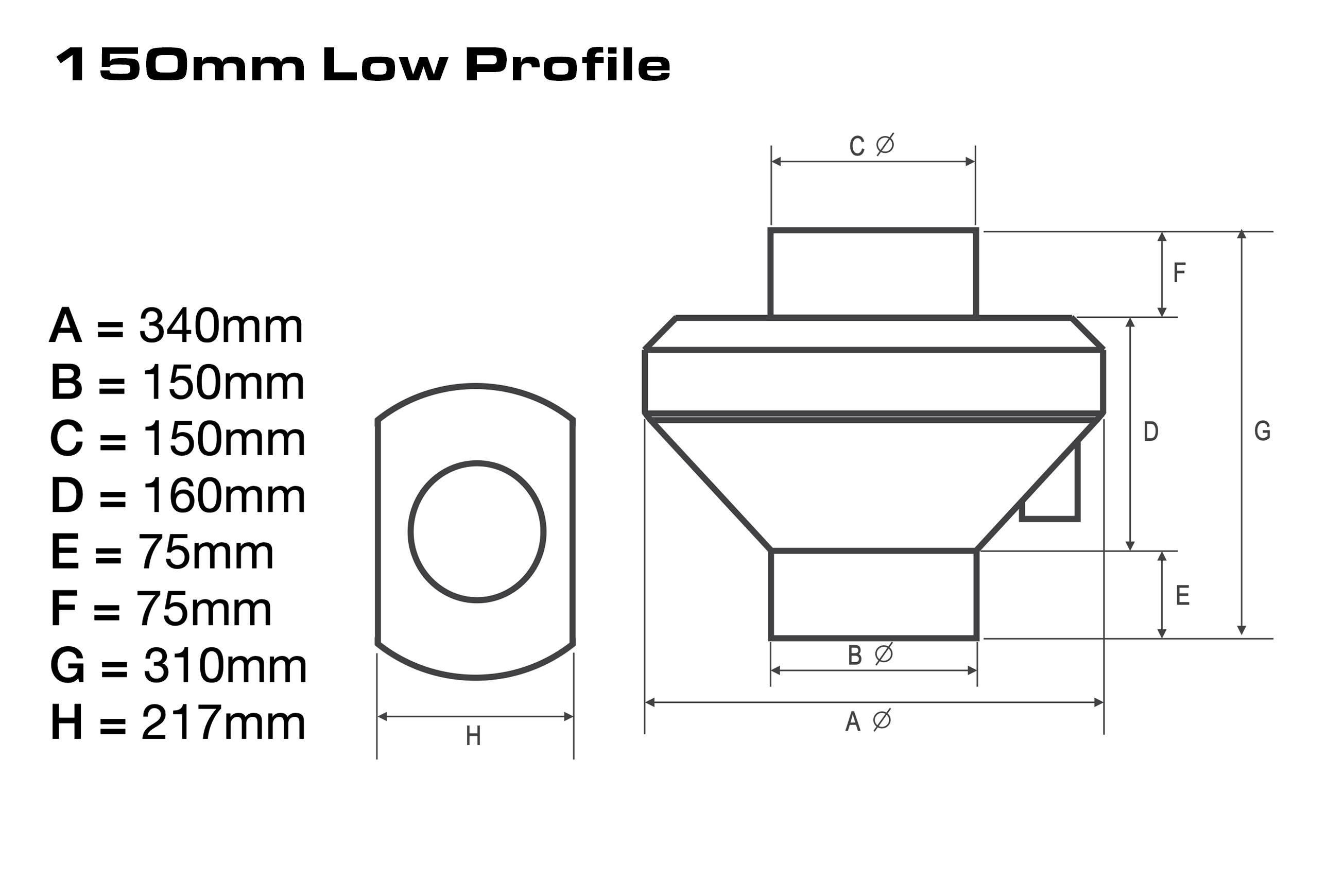

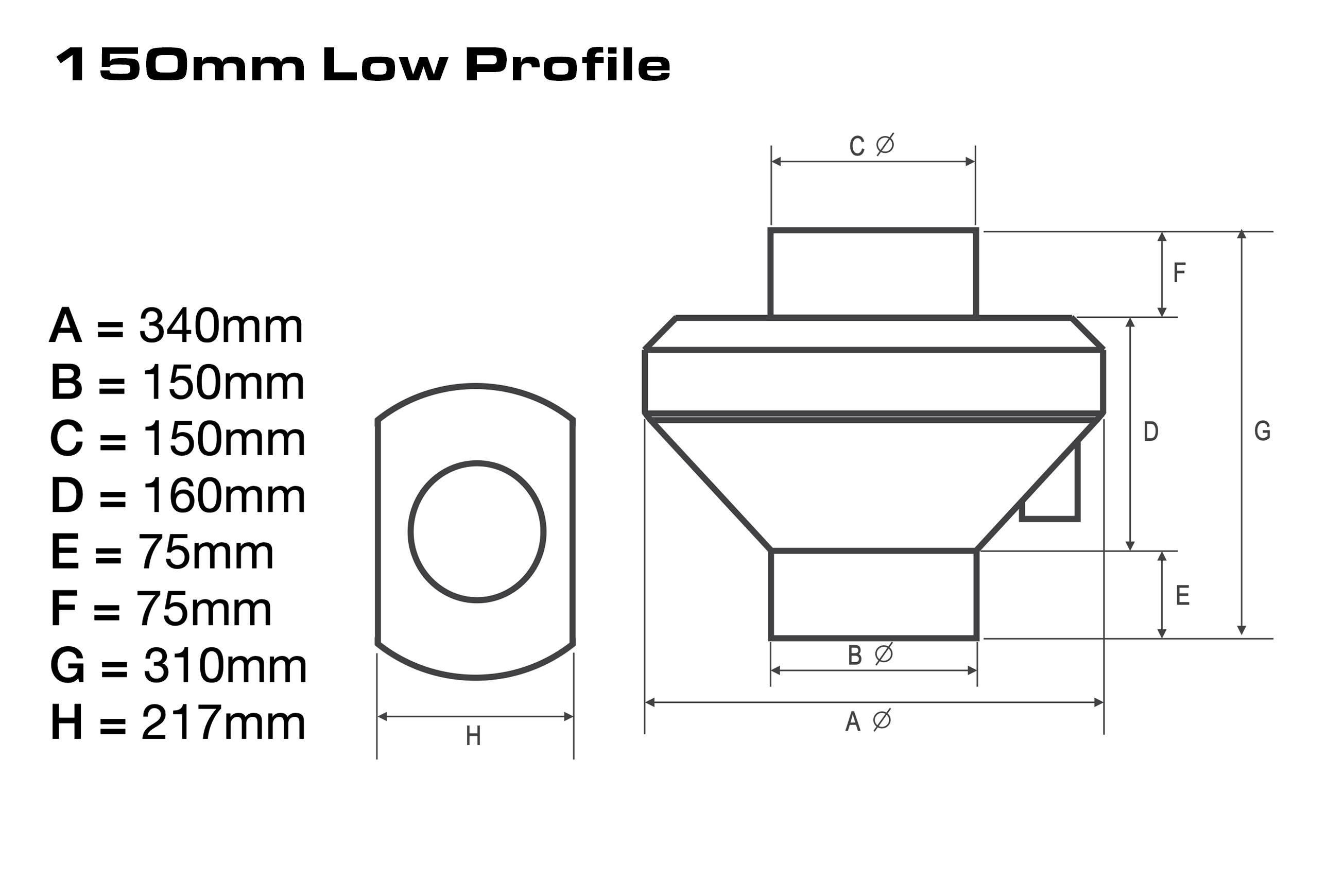

150mm Fan Housing Dimensions

Available with R3G190 Motors

Dimensions

- 340mm width (A).

- 217mm height (H).

- 310mm length (G).

- 150mm duct diameter (B).

250mm Fan Housing Dimensions

Available with R3G220 and R3G225 Motors

Dimensions

- 325mm width (A).

- 325mm height (H).

- 308mm length (G).

- 250mm duct diameter (B).

FAQ

Choosing the right inline fan is critical to achieving reliable airflow, managing moisture, and ensuring your ventilation system performs as intended over the long term. Inline fans are not a one-size-fits-all solution, and real-world performance depends heavily on selecting the correct fan type, understanding pressure requirements, using quality components, and ensuring proper installation.

This FAQ section has been created to answer the most common questions we receive about inline fans, including fan selection, airflow and pressure performance, noise levels, energy efficiency, installation considerations, and ongoing operation. It also explains why centrifugal inline fans significantly outperform axial and mixed-flow fans in ducted applications, and how higher-quality components contribute to quieter, more effective ventilation.

Drawing on over 15 years of real-world installation experience across Australian homes, these answers are designed to help you make informed decisions and better understand how an inline fan should perform once installed — not just on paper. Whether you are selecting a fan for a new installation or comparing different fan types, this section will help clarify what matters, what doesn’t, and how to achieve reliable, long-term results.

If you have a question that isn’t covered here, our team is always available to provide personalised advice based on your application, duct layout, and performance requirements.

An electronically commutated (EC) motor operates from a standard alternating current (AC) power supply but, in design and operation, closely resembles a direct current (DC) motor. It is essentially a brushless, permanent-magnet DC motor with integrated electronic control built directly into the motor housing. This allows EC motors to combine the simplicity and robustness of AC motors with the efficiency, controllability, and smooth operation of DC motors — placing them in a category of their own.

By using this technology, EC fans achieve exceptionally high efficiency, particularly at part-load operation, where traditional motors perform poorly. Lower energy consumption, reduced heat generation, and smoother operation contribute to lower running costs and a longer service life, allowing EC motors to effectively pay for themselves over time. They also provide a range of operational advantages that are often overlooked in basic specifications.

EC motors generate their magnetic fields using permanent magnets in the rotor and electrically energised windings in the stator, similar to a brushed DC motor. However, instead of relying on mechanical brushes for commutation, EC motors use electronic commutation. This is made possible by on-board electronics integrated within the motor itself.

These electronics include a rectifier that converts the incoming AC supply into DC power. An integrated controller then precisely regulates the timing, direction, and magnitude of current delivered to each stator winding. Hall effect sensors continuously monitor the position of the rotor magnets, allowing the controller to energise the correct windings at exactly the right moment.

This electronically controlled sequence of magnetic attraction and repulsion produces smooth, efficient rotation with optimal torque at all speeds. Because the entire process is managed electronically, EC motors allow for precise speed control, continuous performance monitoring, and highly efficient operation across the full operating range — making them ideal for high-performance, low-noise ventilation systems.

AC motors are a cost-effective option that still deliver excellent ventilation performance. They are well suited to ducted systems, operate quietly, and are capable of moving large volumes of air efficiently. AC motors run at a single fixed speed, which is typically the point at which they operate most efficiently. This makes them a reliable, straightforward solution where consistent airflow is required.

EC motors build on this performance by offering advanced control and efficiency across a wider operating range. In real-world use, EC motors are capable of higher airflow, smoother fan rotation, and significantly quieter operation — particularly when run at reduced speeds. At lower fan speeds, EC motors can operate almost silently while consuming very little power, making them ideal for noise-sensitive installations or applications requiring longer daily run times.

Because EC motors feature fully adjustable speed control, airflow can be precisely matched to the size, layout, and moisture conditions of the installation. Unlike traditional motors, EC motors remain highly efficient at all speeds, not just at full output. This results in lower energy consumption, reduced wear on components, and greater long-term flexibility if ventilation requirements change over time.

In summary, AC motors offer excellent value and proven performance, while EC motors provide superior efficiency, control, and ultra-quiet operation for high-performance and future-proof ventilation systems.

Energy Efficiency

EC motor efficiency commonly exceeds 90%, allowing EC centrifugal fans to use up to 70% less energy than conventional AC fan systems. Because power consumption drops rapidly as speed is reduced, running an EC fan at around 80% speed can deliver close to a 50% reduction in energy use, while still maintaining effective airflow. This makes EC fans ideal for continuous or long-duration operation without high running costs.

Ease of Control

EC motors continuously monitor their own operating conditions and automatically adjust power input to maintain high efficiency across the entire speed range. Unlike traditional motors, which are only efficient at one operating point, EC motors remain highly efficient even at very low speeds. Many EC motors can be reduced to around 20% of full speed while still maintaining efficiencies of approximately 85%. Speed control is achieved via simple 0–10 V signals from timers, sensors, or controllers, eliminating the need for complex and inefficient variable frequency drives.

Versatility and Performance

EC motors are capable of operating beyond their nominal rated speeds when required, allowing higher airflow to be achieved from a smaller fan assembly. This enables more compact, flexible system designs without compromising performance. The combination of variable speed control, high efficiency, and compact power density makes EC motors exceptionally well suited to modern ventilation systems where quiet operation, energy efficiency, and adaptable airflow are critical.

Our Low Profile fan housing is specifically designed for installations where access height is limited. With an oval profile measuring 340 mm wide and just 217 mm high, it offers a significantly smaller footprint than standard housings, making it ideal for shallow or restricted spaces without compromising performance.

The latest Low Profile design incorporates updated internal air deflection fins, engineered to guide airflow more smoothly through the housing. These improvements reduce internal turbulence, resulting in marginally higher airflow and slightly lower noise levels compared to the previous Normal Profile version.

By combining a compact form factor with refined internal aerodynamics, the Low Profile fan housing delivers efficient, quiet operation in installations where space constraints would otherwise limit fan selection. This makes it a reliable solution for achieving effective ventilation in low-clearance environments.

EC motors are variable speed motors. They have a 0-10V potentiometer mounted on them to adjust their speed precisely between 0% and 100%.

Our EC centrifugal fans are designed to operate very quietly in real-world installations. When operated at reduced speeds — which is how EC fans are typically used — the noise level drops significantly.

It’s important to understand that decibel ratings on their own can be misleading. Noise figures are usually measured in controlled test conditions and do not account for factors such as ducting, fan suspension, building structure, or operating speed. In practice, EC fans are rarely run at full speed continuously. Their ability to modulate speed means they can deliver the required airflow while operating far more quietly than fixed-speed alternatives. The perceived noise of a fan is influenced far more by how it is installed than by a single published dB figure.

In real installations, our EC fans are mounted using anti-vibration straps, connected to ducting, and often run at reduced speeds for extended periods. This combination results in exceptionally low perceived noise inside and outside the home, even during long operating cycles.

In short, EC fans offer excellent noise control, with the added benefit of being able to fine-tune airflow to achieve effective ventilation without unnecessary sound or energy use.

Decibel ratings are often misunderstood and, in many cases, misused. On their own, dB figures rarely reflect how loud a fan will actually sound once installed in a real building. Unfortunately, some manufacturers take advantage of this by publishing selectively measured or unrealistic noise figures that do not represent real-world performance. Some manufacturers are simply dishonest. Please see our Instagram post HERE and our Instagram video HERE for a good explanation of the issue.

Firstly, decibel ratings are typically measured under laboratory conditions that bear little resemblance to an installed environment. Measurements may be taken at unrealistic distances, at reduced fan speeds, without ducting attached, or in free-air test rigs. This makes it very easy to publish an impressive number that does not translate to real installations in homes.

Secondly, not all noise is perceived equally. The frequency of the sound (its pitch) is often far more important than the overall decibel level. Many fans with low published dB ratings produce a noticeable high-frequency motor “whine”. This type of noise travels easily through building materials and is particularly intrusive to occupants. By contrast, our centrifugal fans predominantly generate airflow noise rather than motor noise. Once installed, airflow noise is largely attenuated by ducting on either side of the fan, while motor whine continues to transmit through structures.

Thirdly, decibel scales are logarithmic, not linear. A small numerical difference in dB can represent a significant perceived difference in loudness, yet manufacturers often quote figures without context or explanation. This makes side-by-side comparisons meaningless unless the test methods are identical and independently verified.

We have been installing ventilation systems for over 15 years and have tested virtually every fan available on the market, including all major competing models. Based on extensive real-world installation experience, we are confident that our fans are quieter in installed conditions than any comparable models currently available.

Importantly, our decibel ratings have been independently tested in Australia by VIPAC Engineers & Scientists Ltd, providing credible, third-party verification rather than marketing-driven claims.

For a clear visual explanation of why published noise figures can be misleading, we recommend viewing our Instagram videos linked above, which break this issue down in simple, practical terms.

In summary, decibel ratings alone do not tell the full story. Installation method, operating speed, sound frequency, fan design, ducting, and vibration isolation all have a greater impact on perceived noise than a single dB number. This is why real-world performance and proven installation experience matter far more than headline specifications.

The fan motors are manufactured by ebm-papst in Germany.

Yes. All of our fan housings are custom injection moulded in Melbourne by Shale HVAC, exclusively for Fresh Ventilation. They are manufactured using high-quality, virgin ABS resin with a V0 fire retardant rating, providing excellent strength, durability, and fire performance.

Producing our fan housings locally allows us to maintain strict quality control, refine designs based on real-world installation feedback, and ensure the housings are suited to Australian conditions. The result is a robust, purpose-built housing that supports quiet operation, reliable airflow, and long-term performance in demanding environments.

Yes. Our fans have been independently tested and certified for Australian electrical safety compliance. They carry the Regulatory Compliance Mark (RCM), confirming they meet the relevant Australian Standards and are registered under the Electrical Equipment Safety System (EESS) for legal sale and safe use in Australia.

All testing and certification was conducted by VIPAC Engineers & Scientists Ltd, an accredited independent testing authority. This provides assurance that our fans meet strict Australian requirements for electrical safety, performance, and compliance, giving you confidence that the equipment is safe, reliable, and approved for use in Australian homes.

For residential electrical installations in Australia, fan motors are required to be manual restart as part of meeting safety expectations under the Regulatory Compliance Mark (RCM) framework.

In this context, manual restart refers to how a motor behaves when a fault is detected, such as overheating or internal electrical failure. A manual restart motor shuts down and remains off once a fault occurs. The motor must then be repaired or replaced before it can operate again. This behaviour is intentional and forms a critical safety mechanism, preventing continued operation of a faulty appliance.

By contrast, auto restart motors are designed to stop temporarily when a fault is detected and then automatically attempt to restart after a delay. If the underlying fault remains, the motor can repeatedly stop and restart. This fault-cycling behaviour significantly increases electrical stress and heat build-up and may cause a fire.

Australian residential electrical safety requirements are deliberately conservative in this regard. The expectation is that appliances installed in homes should not repeatedly re-energise themselves after a fault, as this presents an unacceptable fire risk.

Many fans available on the Australian market are nevertheless auto restart. This is largely because they are designed for overseas markets where this requirement does not exist. Australia represents a very small portion of the global fan market, and many manufacturers simply supply globally standard products that are compliant elsewhere but not appropriately configured for Australian residential use. In many cases, this distinction is not clearly disclosed.

Based on our understanding of the local market, we believe our fans are among the very few available in Australia that are genuinely manual restart, specifically selected and configured to meet Australian residential electrical compliance expectations under RCM.

This is not a marketing feature — it is a safety requirement. And it is one that is often overlooked.

The fan motors have a 5 year warranty.

EC motors have a protection rating of IP 54.