Subfloor Ventilation Guide

Mechanical Subfloor Ventilation Systems

Sub Floor Ventilation Can Remove Ground Moisture from Underneath Raised Floors, Creating a Drier and Warmer Sub Floor Area

Many pests and building inspectors recommend sub floor ventilation to reduce termite risk. These systems are very effective in homes that experience a continuing musty odour or where there is mould on shoes and clothes in wardrobes or on furniture in living spaces.

Your sub floor area may seem insignificant because it does not form part of your living room. However, the fact of the matter is that this space actually has a high impact on the quality of air you breathe in while you are indoors and may affect your health. Poorly ventilated sub floor areas are often damp. This dampness can result in mould, mildew, musty odours, wood rot and pest infestation in your sub floor area and can also contribute to the spread of mould, mildew and allergies above.

Problems Solved with Subfloor Ventilation

Modern homes are well insulated and sealed tight to increase energy efficiency, but are more likely to have poor ventilation because they cannot breathe. Opening doors and windows is not always practical and does not provide adequate ventilation, which needs movement and exchange of air.

Sub floor ventilation systems offer a range of benefits:

Rising damp

Rising damp carries soluble salts up into the masonry, known as efflorescence. This dampness affects the quality of air that you breathe while you’re indoors. A damp home with low ventilation has air that contains pollutants which can trigger the development of asthma and other respiratory-related infections, as well as allergic reactions.

One of the main problems when homes are damp is the development of mould, usually on the wall. As a result, allergens are produced. Even if your home is clean and dust-free, you may find yourself sneezing, experiencing itchy eyes or a runny nose when you come into contact with the spores produced when mould grows from a damp area in your property from lack of air flow. Another danger associated with rising damp issues is the fact that it creates an environment for the development and multiplication of harmful bacteria such as mould.

Rising damp can be a homeowner’s worst nightmare as the building structure can be affected by rising damp. The integrity of the foundations can be seriously put at risk due to rising damp.

Another culprit for rising damp is the age of your home. Homes built before 1980 are often found with damp rising in capillary action in the brick work or masonry due to the fact that the walls were either inferior or had no damp course. The internal walls of these older homes have a more common issue with water penetration. Building regulations have since been updated over the years to include items to help prevent this problem from occurring. There is a damp treatment and solution for each reason of rising damp.

Whenever a home has a rising damp issue, the main reason behind it is usually the high levels of moisture in the air and the lack of natural sub floor ventilation. There are many situations that can lead to different house structures having rising damp and therefore creating places for mould to grow.

A common area in the home that can create rising damp is under the house – the sub floor area. The sub floor area can easily harbour ground moisture, causing rising damp throughout your home’s masonry structure. Mould, usually on the walls inside your home, is a sign of rising damp. Rising damp can also cause pest problems when located at ground level. The damp conditions can be a magnet for termites who like to eat the damp wood. This occurs especially when there is insufficient air flow. A leaking pipe beneath your floor can also cause the sub floor area of your property to become damp, more so when there aren’t enough vents or a sub floor ventilation system that can facilitate proper circulation of air. Rising damp at floor level can weaken the structure of the wall. Masonry walls can begin to crumble.

Additionally, metallic material will experience corrosion, causing damage to the entire building. Rising damp is a real risk to your property, but sub floor ventilation can easily eradicate and prevent rising damp from developing. It is one of the best rising damp solutions.

Damp and/or mouldy home

Mould is almost always caused by dampness and poor ventilation in your home.

The signs of dampness and poor ventilation can often be quite obvious.

However, in newer homes, which are built to be almost airtight under building regulations, signs of poor ventilation aren’t always initially visible and may exist in the form of excessive moisture that can’t escape and hidden damp, which accumulates over time.

Musty odours

Musty odours, caused by dampness and poor ventilation in your home, are pretty off-putting and not particularly healthy.

Getting clean, fresh air in regularly through your home with proper ventilation will help greatly with lingering smells, flushing out the stale, contaminated air along with any musty odours.

Wood rot and/or termites

Wet wood rot is due to water damage that may accumulate slowly over time, such as with leaking pipes or penetrating damp caused by the presence of moisture in the air. Wet rot will generally grow in humid conditions. Any piece of wood present in the home that is not protected is vulnerable to wet rot.

Termites are tiny insects that feed on wood. Rotting wood is more likely to attract termites. This is especially true of wet rot which contains plenty of moisture that the termites seek along with nutrients. Dry rot is not as conducive to termites, but they may still be present.

Condensation

If you know your home has weeping windows, you’re definitely not alone. Thankfully, fixing window condensation can be as simple as improving the ventilation in your home.

Condensation forms on cold surfaces when they come into contact with moisture in the air. Dripping condensation and excessive moisture can result in a number of issues for your home and your family’s health.

Types of Subfloor Ventilation

Fresh Ventilation supplies and installs a range of efficient and technologically superior sub floor ventilation products. Our systems utilise the latest in ventilation technology, with Australian made components and German made AC or EC motor centrifugal fans by ebm-papst.

Fresh Ventilation Ducted Sub Floor Ventilation Systems

These systems are superior.

Our own exclusive design, based on years of experience and trialling competing products. This system uses ducting and centrifugal fans and can be installed in almost any sub floor area.

Wall-Mounted Sub Floor Ventilation Systems

Fresh Ventilation do not recommend or install wall-mounted sub floor ventilation products unless no other alternative is available. Wall-mounted systems have substantial limitations by design and mostly use inferior and noisy components further limiting their usefulness.

When access to a sub floor area is not possible, it may be possible to install wall-mounted fans. In this situation, the limited ventilation provided is better than none. Ask us how we can help if this applies to you.

Solar Sub Floor Ventilation Fans

While we are firm believers in the benefits and need for solar (we have 21kW of it on our roof), unfortunately solar sub floor ventilation fans do not work.

Solar sub floor ventilation systems typically use very low wattage axial fans. Axial fans don't cope well with pressure, which means when ducting is installed airflow volume is severely reduced.

Solar sub floor fans are very noisy. On the numerous occasions we have installed them (against our recommendation) the biggest complaint received has been the noise!

Lastly, solar sub floor ventilation fans don't work well when it's cloudy, overcast, or raining - they often don't work at all on such days! Unfortunately, this is when you need them the most!

Passive Sub Floor Ventilation

Passive sub floor ventilation includes any form of opening in the external walls of your sub floor area, such as weep holes, terracotta vents, wire mesh vents, and doors.

Passive sub floor ventilation is not effective if you are experiencing a mould and damp problem in your sub floor area. This is because it does not guarantee movement and exchange of air.

Cross-flow ventilation is nearly always impossible without mechanical subfloor ventilation. Air is lazy, so you can bet on it taking the path of least resistance. That’s why air always takes the easy way out as it moves through a sub floor space (assuming it even enters through restrictive passive vents in the first place). It’s much easier for air to pass through a large open section near the point of entry than to flow around multiple corners into small closed-off sections.

Having mechanical ventilation extracting stale air from these small closed-off sections creates cross-flow ventilation. This is because Air Out = Air In! Airflow is measured in cubic metres per hour (m3/h). For every cubic metre of stale air that gets drawn out from a space, 1 cubic metre of fresh air must get drawn in to the space. As the fans continually draw air out, fresh air enters through existing openings and works its way through the sub floor area to the point of extraction.

Ducted Subfloor Ventilation Systems

Ducted sub floor ventilation systems have significant advantages:

Duct can be run to problem areas.

The ability to have multiple pickup points means coverage is far greater.

Smart design can achieve excellent cross-flow ventilation.

Stale air can be drawn from deep in the sub floor area.

Premium centrifugal fans are much quieter than most wall-mounted fans and outperform axial wall-mounted fans in a ducted system.

What Makes Fresh Ventilation Different

Fresh Ventilation is a family owned and operated business. Our business has specialised in the installation of premium quality ventilation systems for over 10 years.

Effective sub floor ventilation requires quality components and proper installation. Given that no two sub floor areas are the same, there is no one-size-fits-all solution to sub floor ventilation. This is why we place a strong emphasis on customised solutions and after-sales support to help you get the most from your system.

Our focus is on premium products and expert advice to create ventilation systems that actually work.

Our Subfloor Ventilation Systems

Fresh Ventilation’s exclusive design is based on years of knowledge, experience and trialling competing products. Our systems use components that have been carefully selected for their purpose to ensure that you get superior performance, proven reliability and lower operating costs.

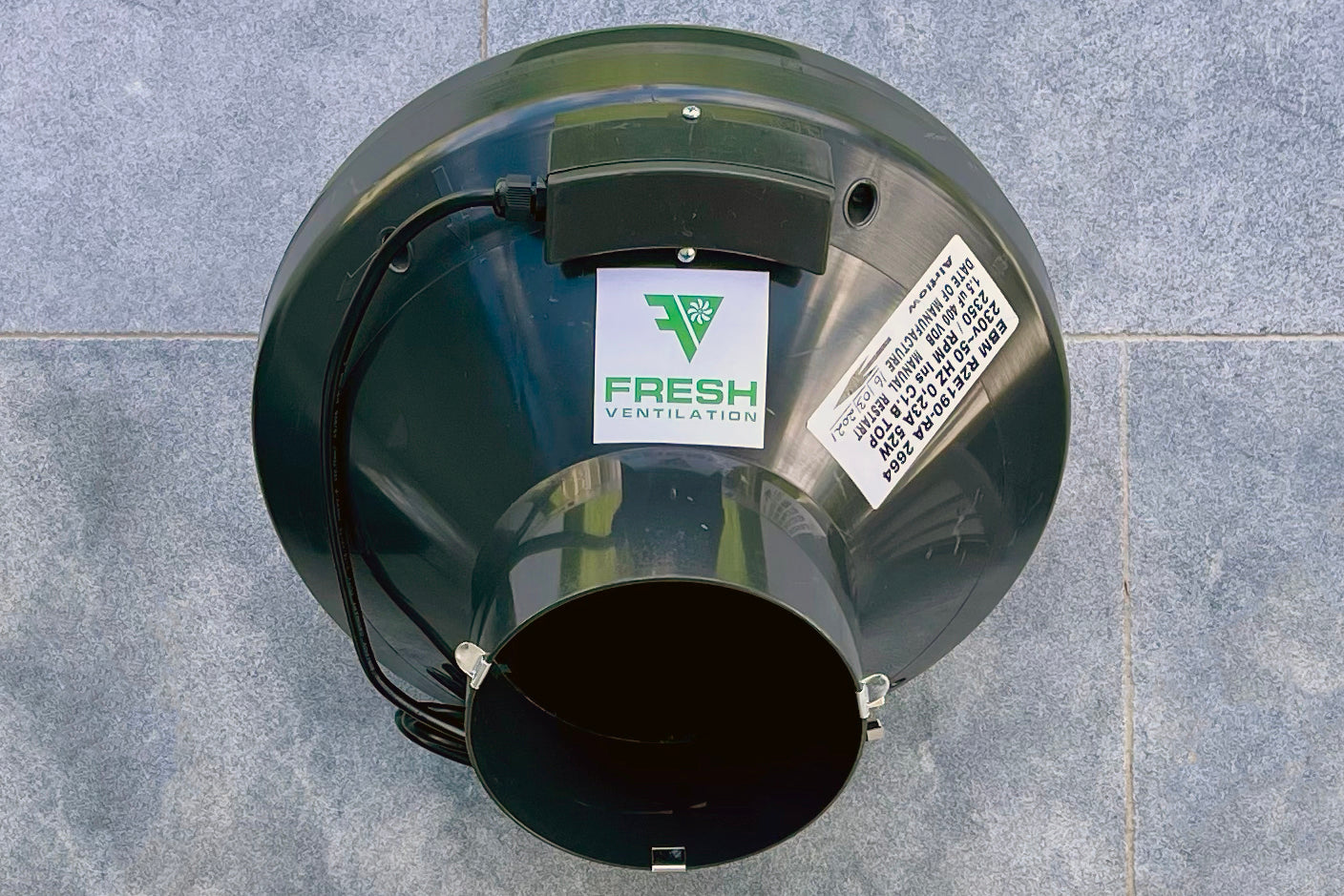

We use Australian made components, including ducting and fittings, and German made centrifugal fans with both AC and EC motors available.

Fan Specifications

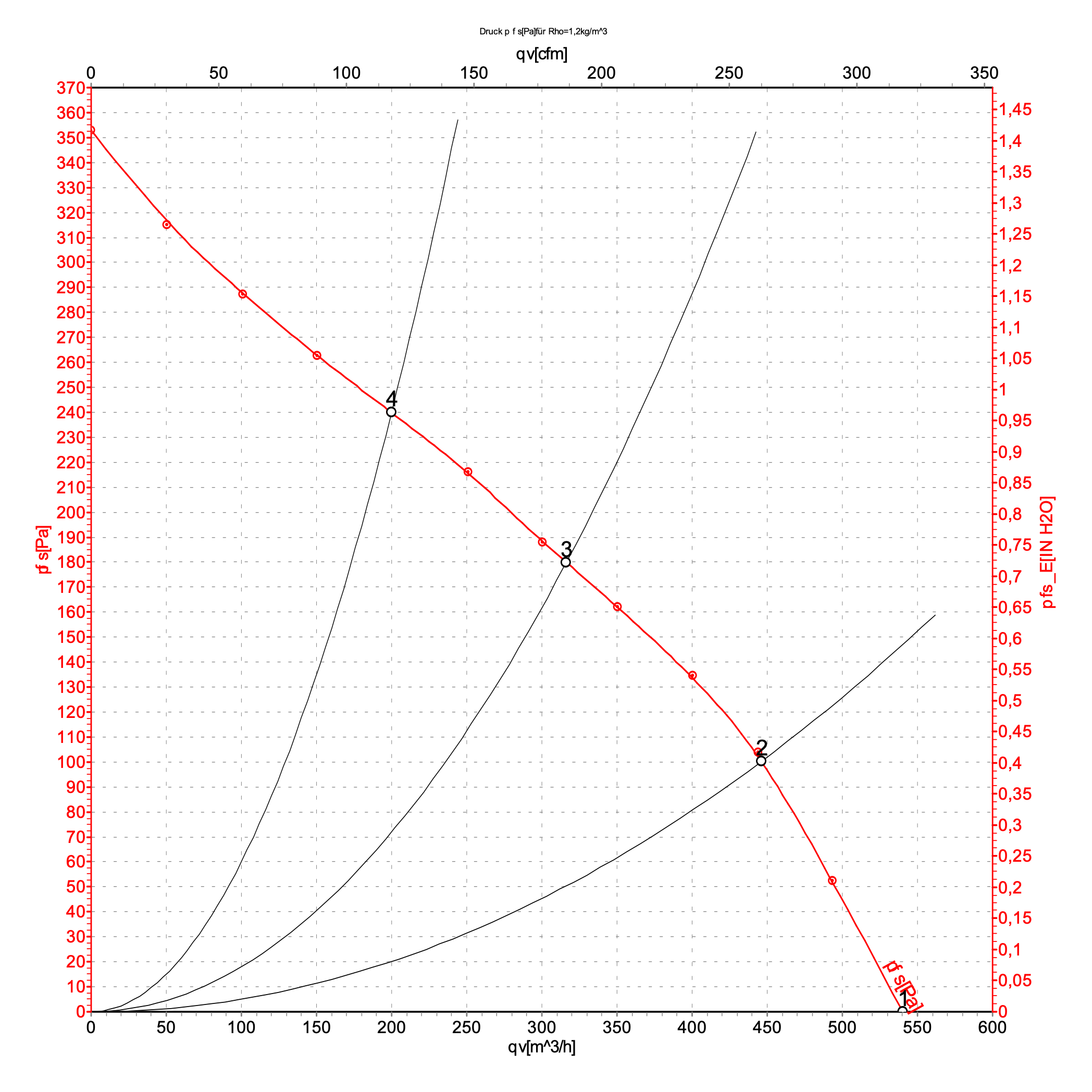

AC Motor Centrifugal Fans

Specifications

- Single speed or three speed (low profile only).

- Approximately 540 m³/h air flow and 48 W power usage.

- 37 dB(A) breakout sound pressure at 100% speed. Please see our FAQ section below on why decibel ratings are misleading.

- 34 dB(A) breakout sound pressure at 75% speed. Please see our FAQ section below on why decibel ratings are misleading.

- 27 dB(A) breakout sound pressure at 50% speed. Please see our FAQ section below on why decibel ratings are misleading.

- 353 Pa pressure max at 100% speed.

- R2E190 motor manufactured by ebm-papst in Germany.

- Custom Australian made fan housing.

- 5 year warranty.

- IP 44 protection rating.

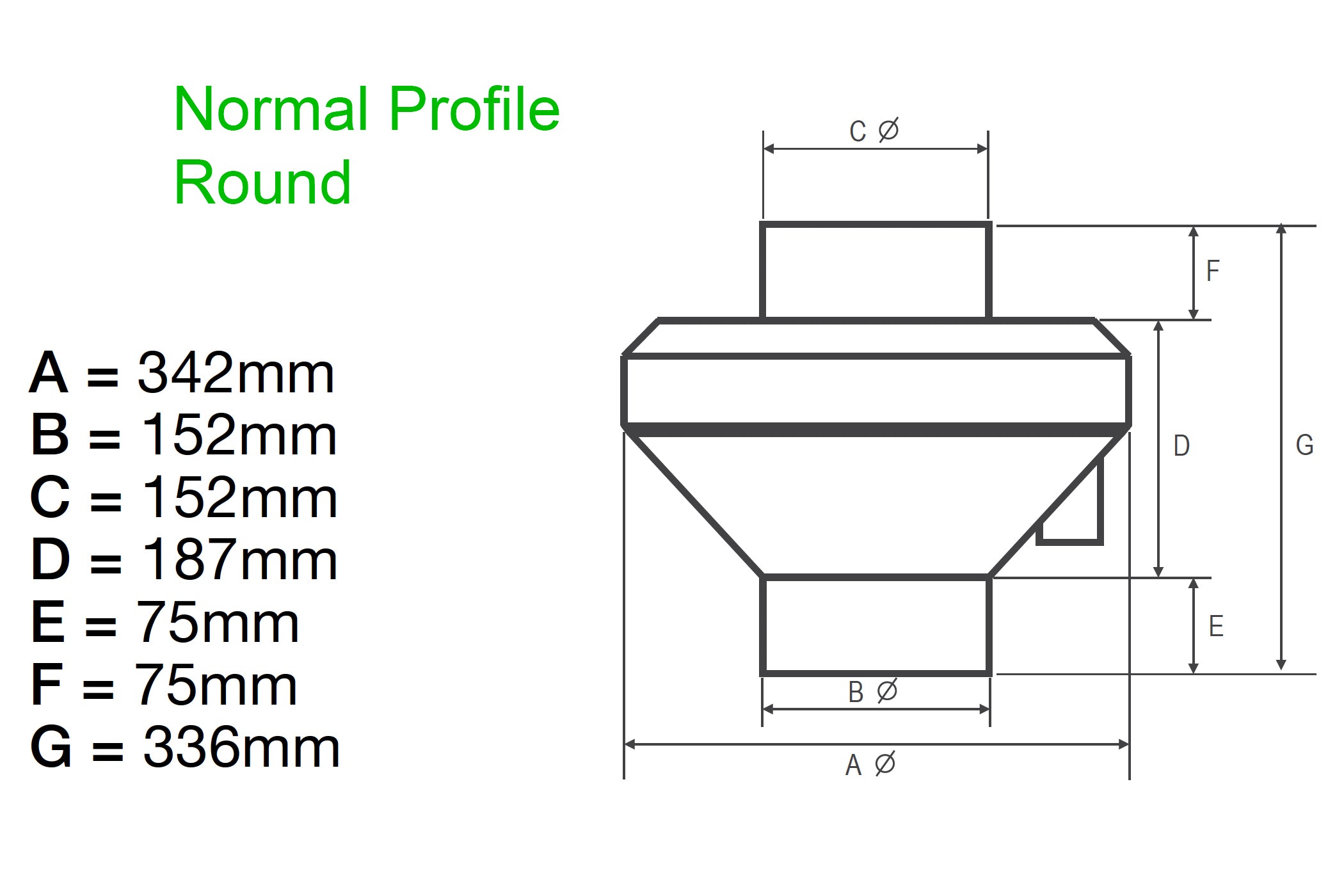

Normal Profile Dimensions

- 342mm width (A).

- 342mm height (A).

- 336mm length (G).

- 150mm duct attachment flange diameter (B).

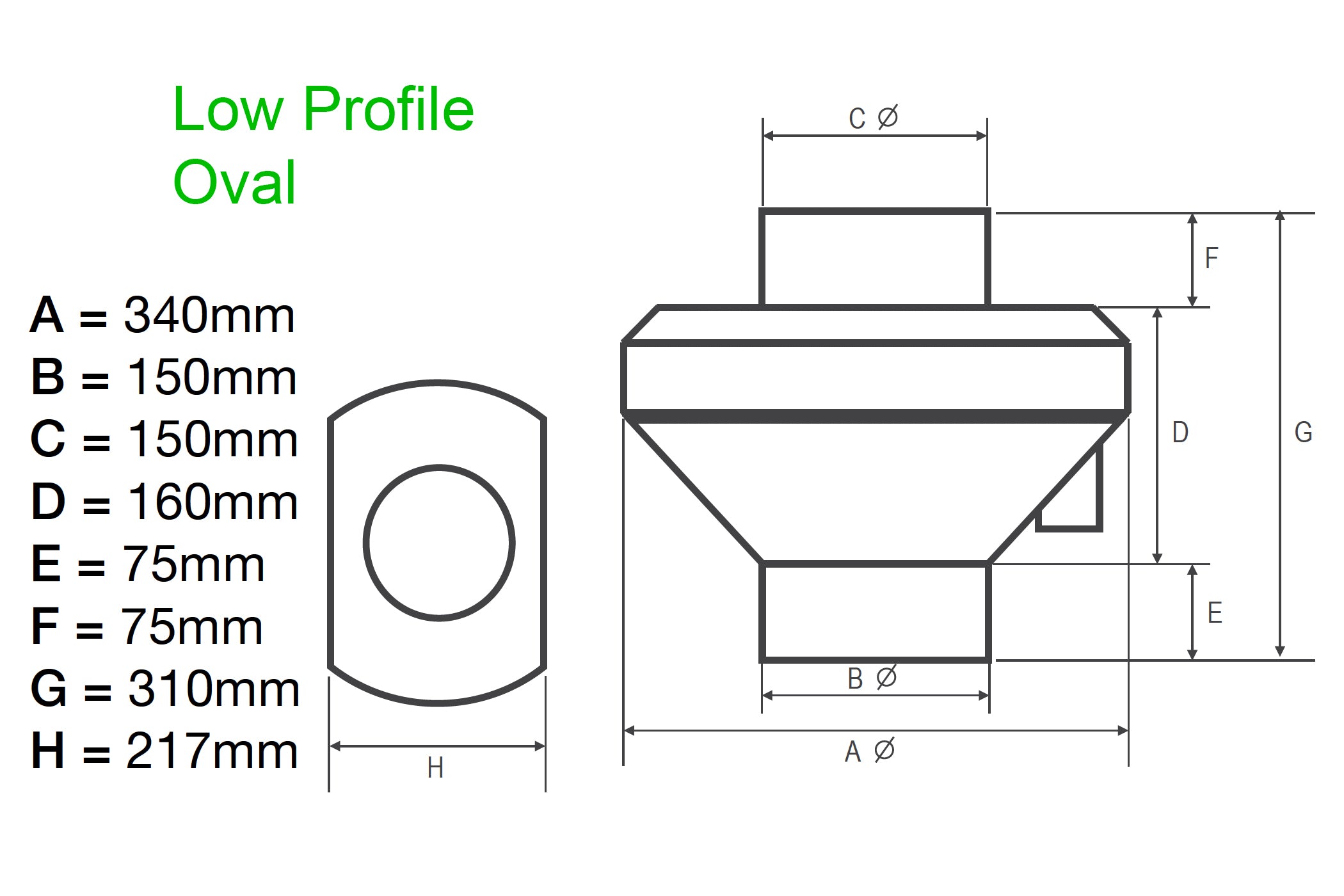

Low Profile Dimensions

- 340mm width (A).

- 217mm height (H).

- 310mm length (G).

- 150mm duct attachment flange diameter (B).

Fan Specifications

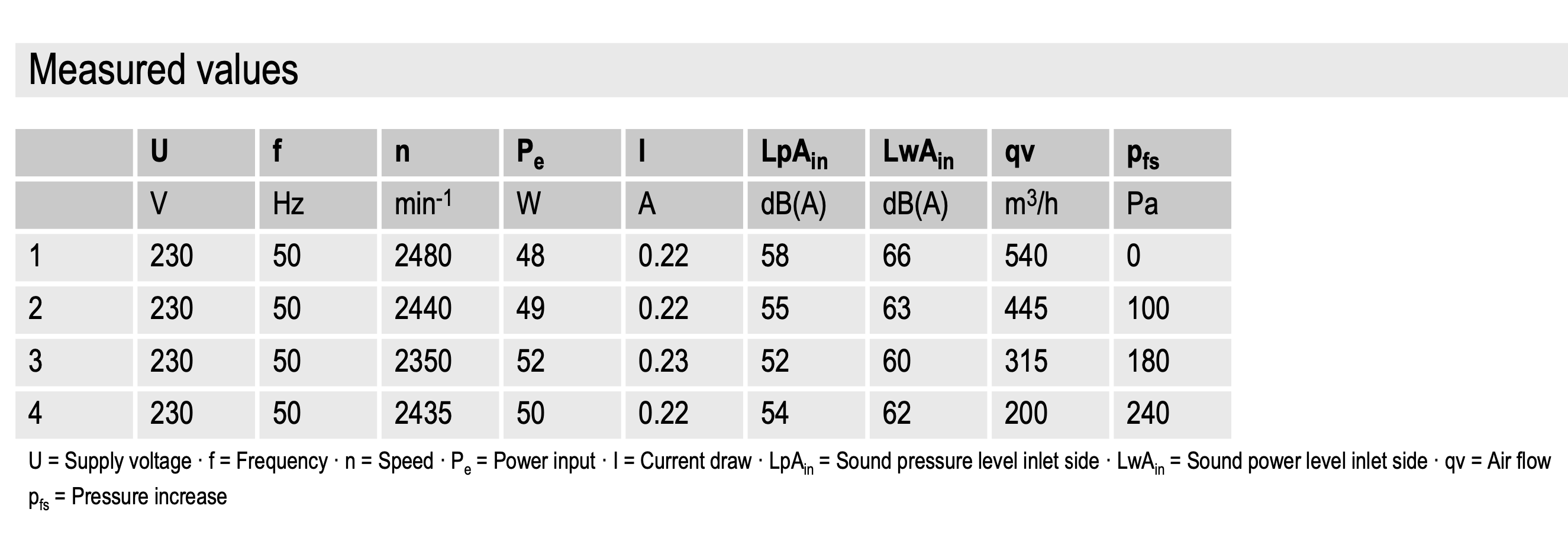

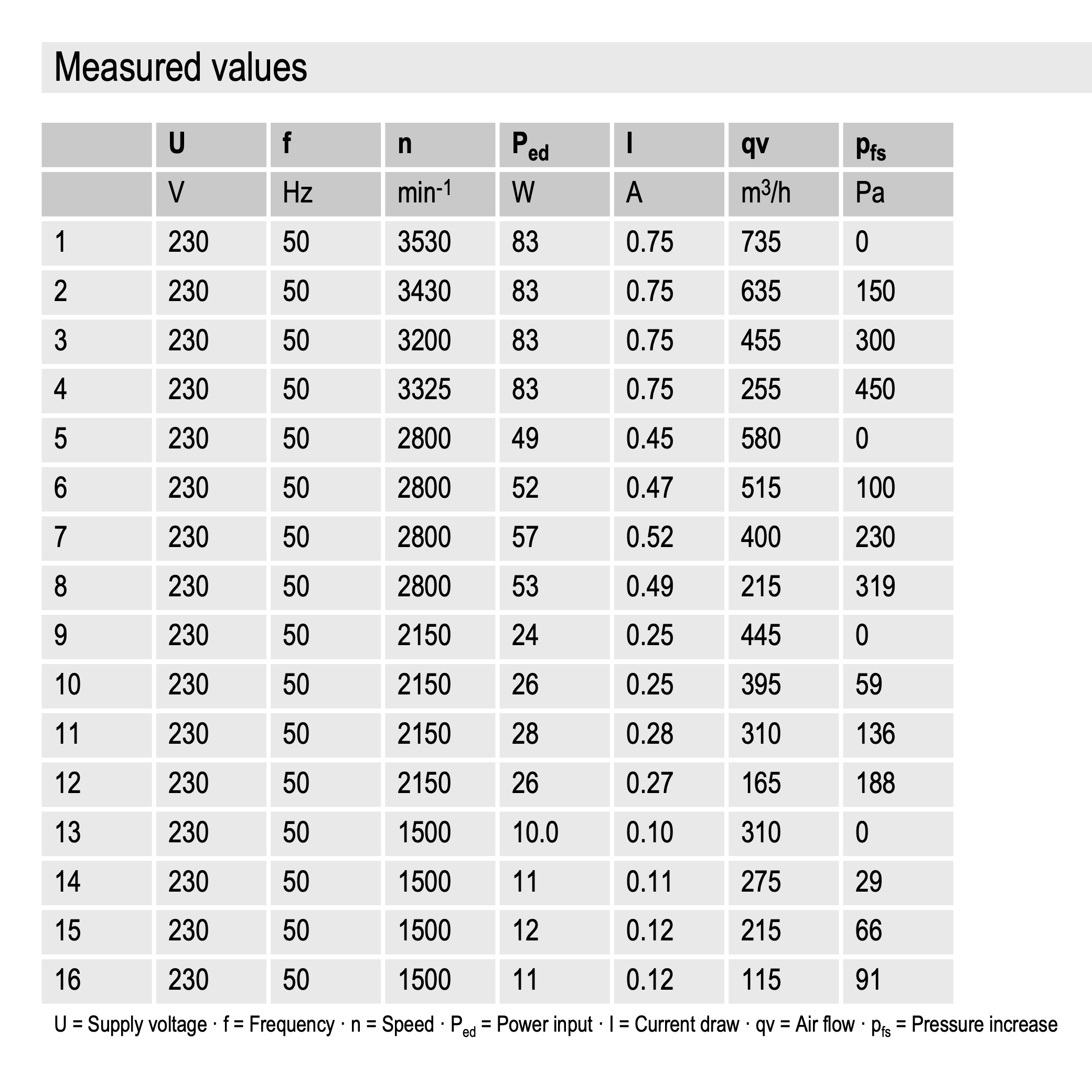

EC Motor Centrifugal Fans

Specifications

- Variable speed.

- 45-48 dB(A) breakout sound pressure at 100% speed. Please see our FAQ section below on why decibel ratings are misleading.

- 25-27 dB(A) breakout sound pressure at 30% speed. Please see our FAQ section below on why decibel ratings are misleading.

- R3G190 motor manufactured by ebm-papst in Germany.

- Custom Australian made fan housing.

- 5 year warranty.

- IP 54 protection rating.

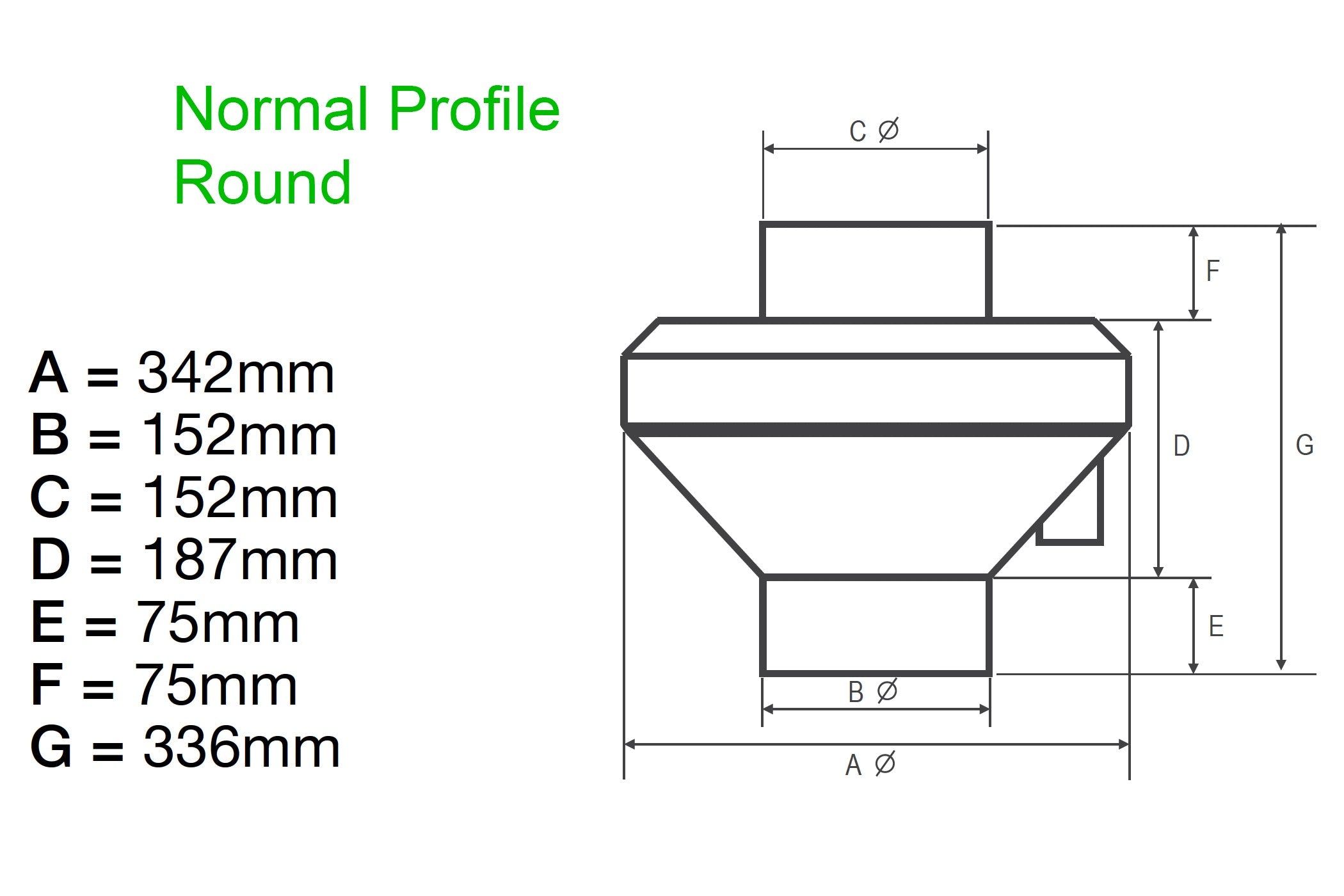

Normal Profile Dimensions

- 342mm width (A).

- 342mm height (A).

- 336mm length (G).

- 150mm duct attachment flange diameter (B).

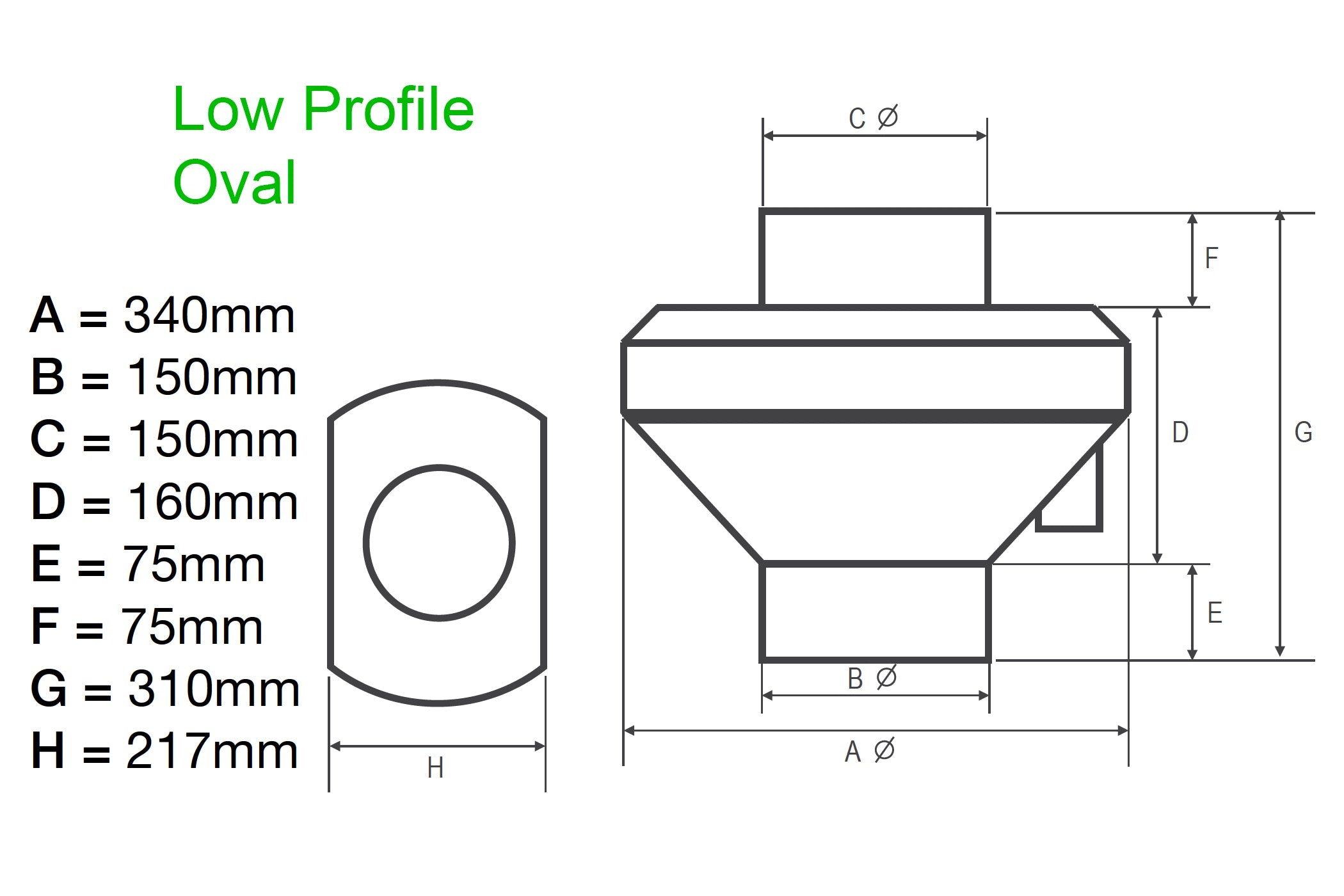

Low Profile Dimensions

- 340mm width (A).

- 217mm height (H).

- 310mm length (G).

- 150mm duct attachment flange diameter (B).

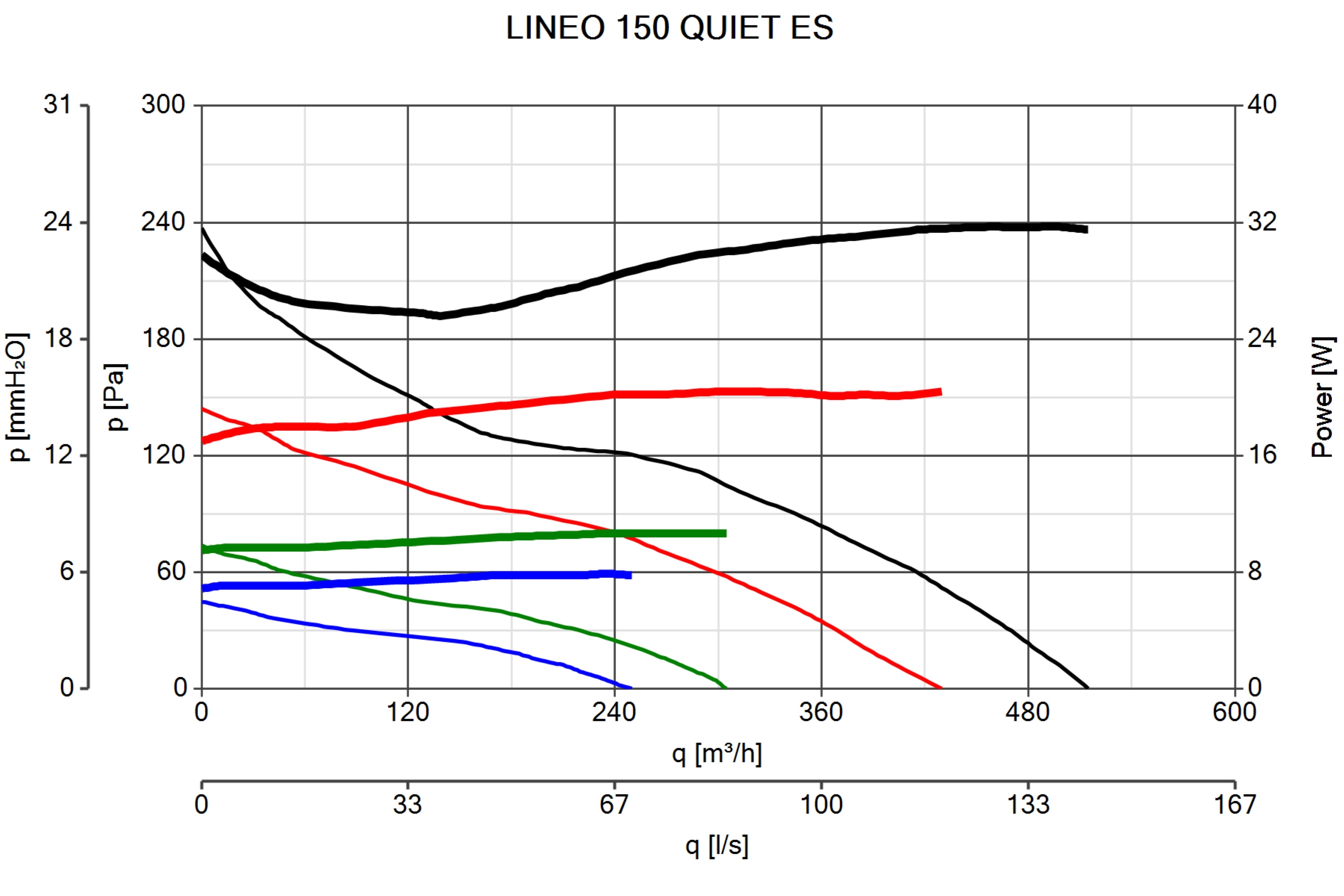

100% Speed (10V)

- Maximum Absorbed Power: 83W.

- Maximum Delivery: 735 m³/h.

- Pressure Max: 825 Pa.

- RPM: 3,530.

80% Speed (8V)

- Maximum Absorbed Power: 49W.

- Maximum Delivery: 580 m³/h.

- Pressure Max: 369 Pa.

- RPM: 2,800.

60% Speed (6V)

- Maximum Absorbed Power: 24W.

- Maximum Delivery: 445 m³/h.

- Pressure Max: 218 Pa.

- RPM: 2,150.

40% Speed (4V)

- Maximum Absorbed Power: 10W.

- Maximum Delivery: 310 m³/h.

- Pressure Max: 105 Pa.

- RPM: 1,500.

Fan Specifications

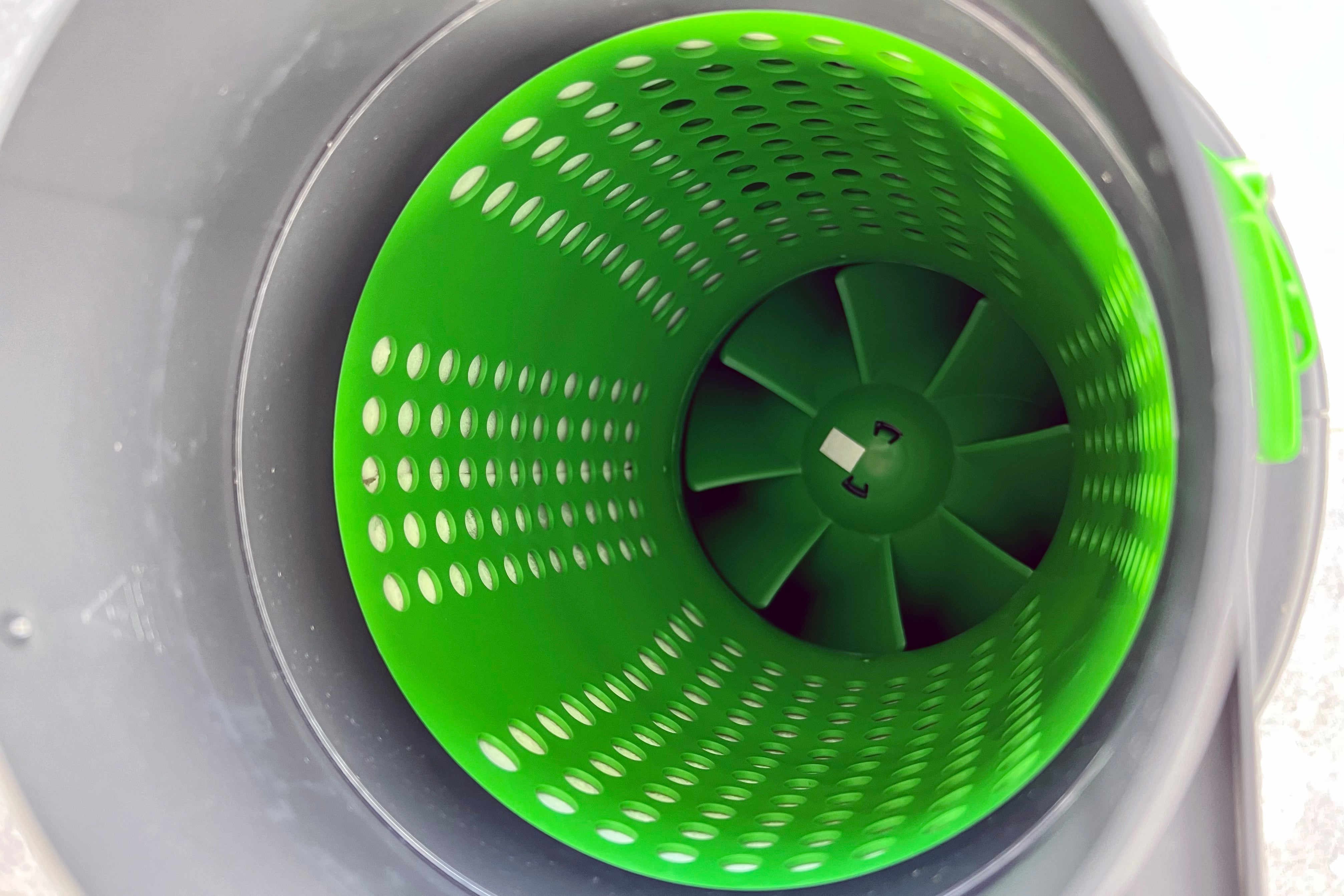

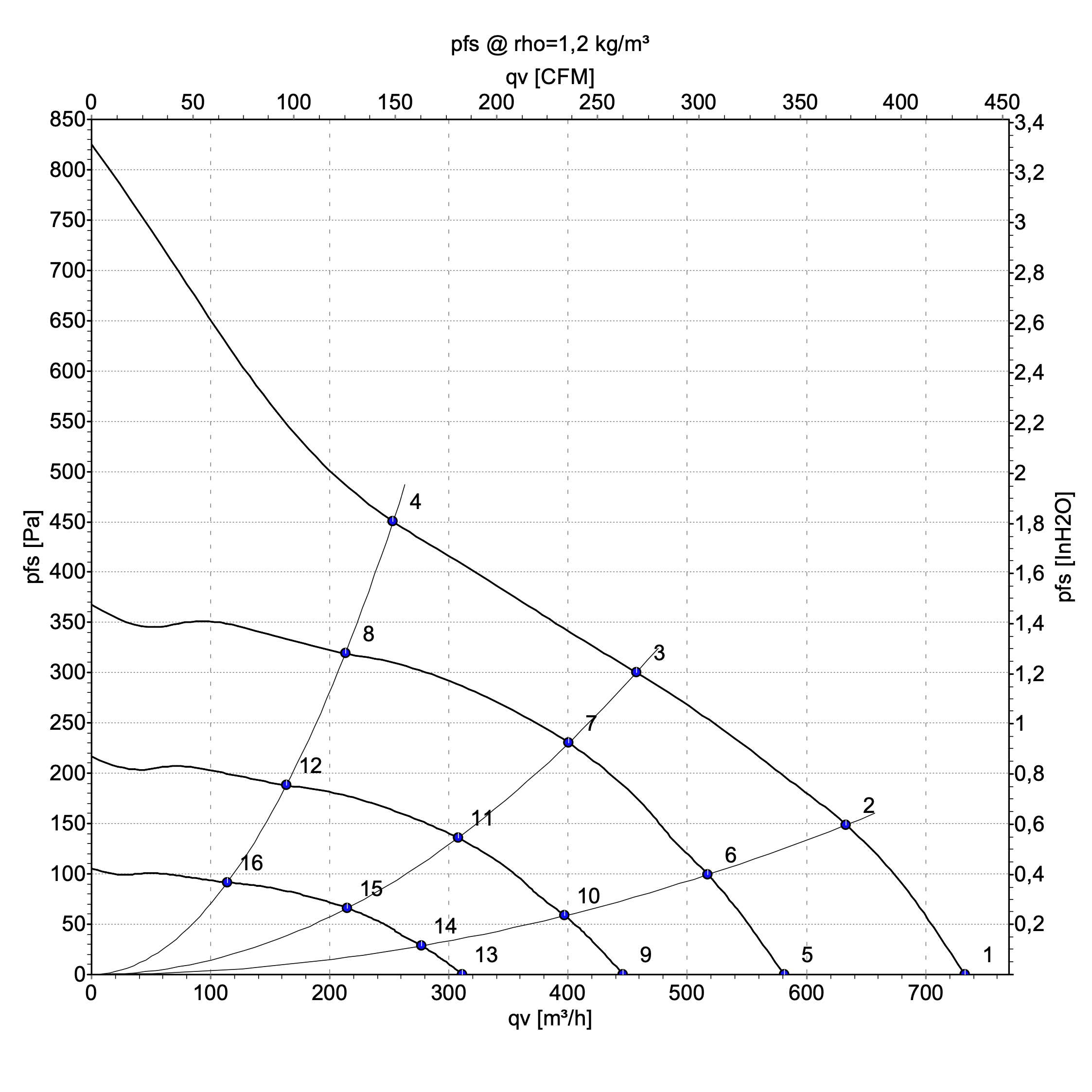

EC Motor Super Quiet Mixed Flow Fans

Specifications

- Suitable for commercial use.

- Enclosures made of fire resistant plastic resin.

- Casing integrating a sound-absorbing coating, optimised to minimise sound emissions radiated into the environment and transmitted through exhaust and supply ducts.

- High water resistance: IPX5.

- Equipped with a thermal fuse overheating safety device.

- Speed adjustable through optional potentiometer (0-10V signal).

- Long life 30,000 hour motor.

- Double insulated housing (does not require an earth).

- Made in Italy.

- 2 Year Warranty.

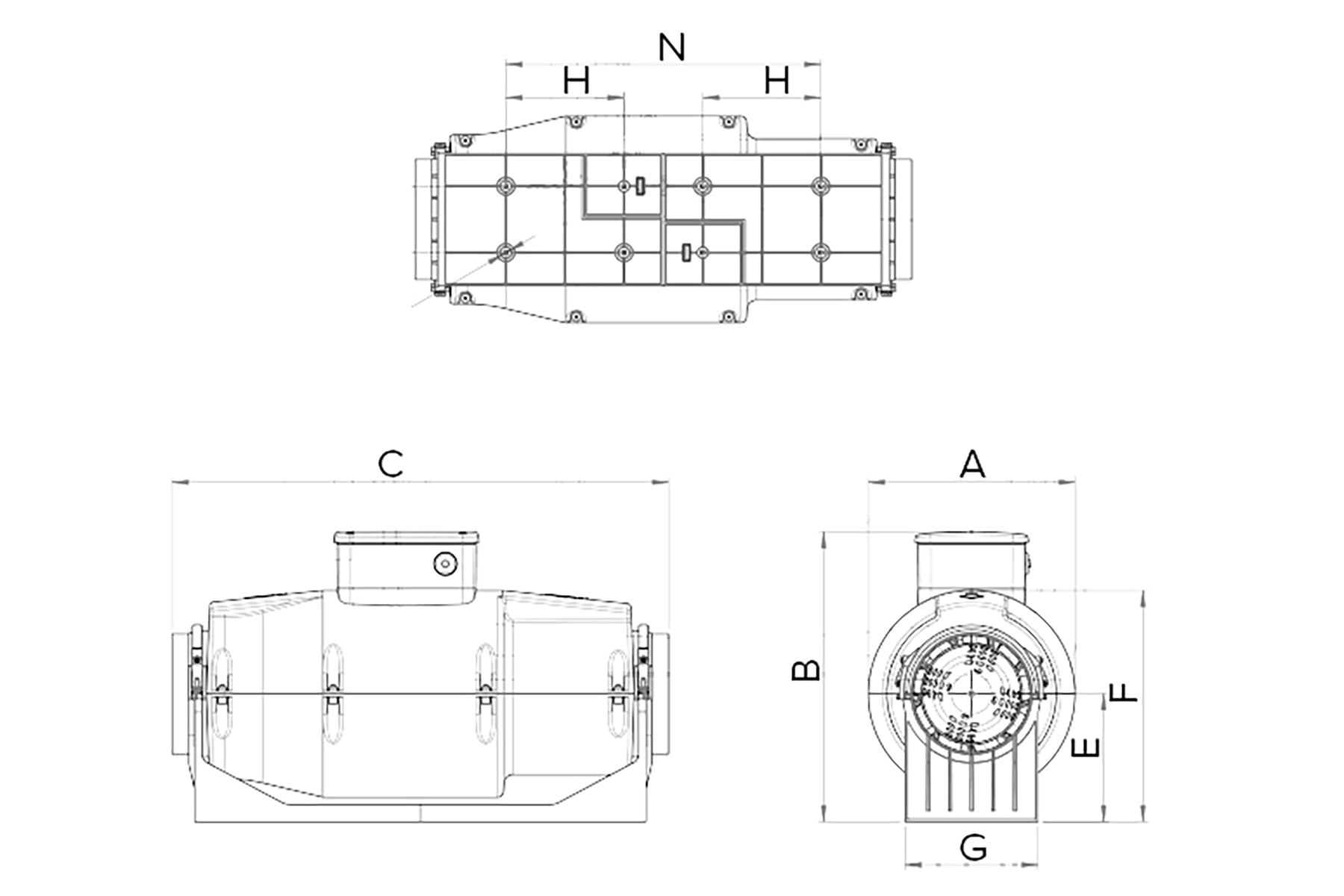

Dimensions

- 232mm width (A).

- 320.6mm height (B).

- 685mm length (C).

- 147mm duct attachment flange diameter (D).

- 5.4kg weight.

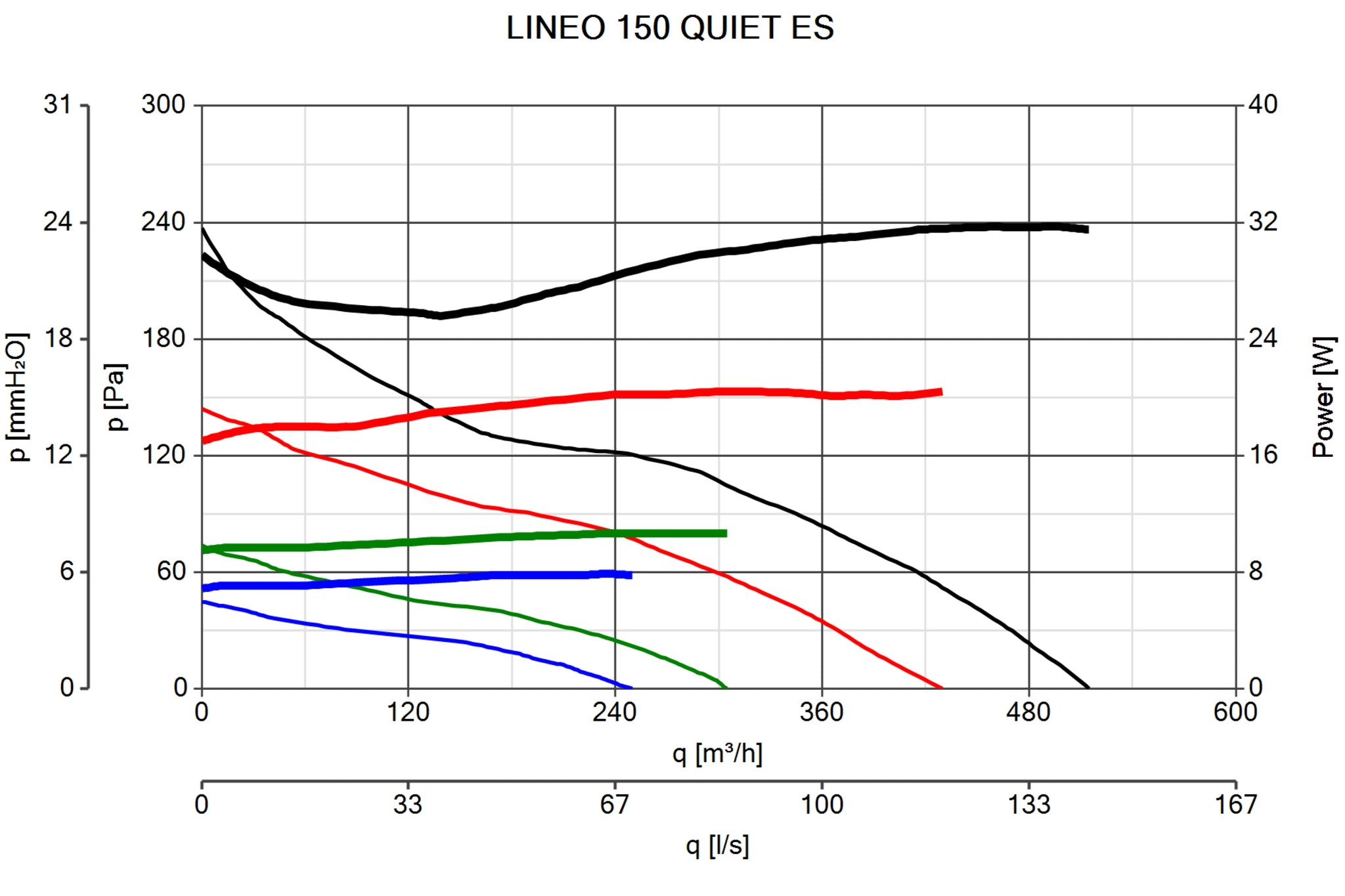

100% Speed (10V)

- Maximum absorbed power: 31 W.

- Maximum delivery: 515 m³/h.

- Pressure max: 237.3 Pa.

- RPM: 2,030.

- Sound pressure Lp 3m breakout: 31 dB(A).

80% Speed (8V)

- Maximum absorbed power: 20 W.

- Maximum delivery: 430 m³/h.

- Pressure max: 144.2 Pa.

- RPM: 1,700.

- Sound pressure Lp 3m breakout: 26 dB(A).

60% Speed (6V)

- Maximum absorbed power: 10.6 W.

- Maximum delivery: 305 m³/h.

- Pressure max: 73.6 Pa.

- RPM: 1,240.

- Sound pressure Lp 3m breakout: 18.6 dB(A).

40% Speed (4V)

- Maximum absorbed power: 7.7 W.

- Maximum delivery: 250 m³/h.

- Pressure max: 45.1 Pa.

- RPM: 1,015.

- Sound pressure Lp 3m breakout: 13.7 dB(A).

FAQ

What is the difference between AC motors and EC motors?

AC motors are cheaper than EC motors but still provide excellent performance. They are very quiet during operation and move large volumes of air through ducting. They operate at one fixed speed where they are most efficient.

In real world use, EC motors provide even higher air flow, are extremely quiet during operation, are capable of silent operation at reduced fan speeds, have smoother fan rotation, and consume almost no power at reduced fan speeds. EC motors have adjustable speed and are very efficient at all speeds.

What is an electronically commutated EC motor?

An electronically commutated (EC) motor is designed to run on an alternating current (AC) power supply, but it in fact bears a closer resemblance to a direct current (DC) motor. It is essentially a permanent magnet, brushless DC motor that incorporates on-board electronics. The added electronics allow an EC motor to combine the best features from both AC and DC motors, and then improve on them. For this reason, an EC motor is in a category of its own.

By utilizing this technology, EC fans are highly efficient and pay for themselves through lower operating costs and extended service life. They also provide many operational benefits that are often overlooked.

EC motors use permanent magnets and electrical windings to generate their magnetic fields, in a similar fashion to brushed DC motors. However, as their name suggests, they achieve commutation electronically rather than mechanically. This is only possible by incorporating on-board electronics within the housing of an electronically commutated EC motor.

The on-board electronics include a rectifier that converts the AC supply to DC. An integrated controller then directs the right amount of current, in the right direction, at the right time, through each of the windings. This develops magnetic poles in the stator, which interact with the permanent magnets in the rotor.

The position of each magnet is determined by using Hall effect sensors. The appropriate magnets are attracted, in sequence, to the magnetic poles in the stator. Simultaneously, the rest of the stator windings are charged with the reverse polarity. These attraction and repulsion forces combine to achieve rotation and produce the optimal torque. Since this is all done electronically, precise motor monitoring and control are possible.

What are the advantages of an electronically commutated EC motor?

Energy Efficiency

EC motor efficiency is often above 90%, allowing EC fans to consume up to 70% less energy, when compared to conventional fans. Running an EC fan at 80% speed saves nearly 50% of the energy.

Ease of Control

By continuously monitoring motor functions and automatically adjusting the control input, high efficiency is maintained throughout the operable speed range. EC motors are often capable of being turned down to 20% of full speed, while still maintaining 85% efficiency. Sensors that produce a 0-10V signal provide speed control without the need for a complex variable frequency drive.

Versatility

EC motors are capable of exceeding rated speeds. This allows fans with EC motors to achieve higher capacity within a smaller fan package.

Why are decibel ratings misleading?

Decibel ratings are misleading, and many manufacturers are simply dishonest. Please see our Instagram post HERE and our Instagram video HERE for a good explanation of the issue.

We've been installing fans for over 10 years. In that time we've tried everything available on the market, including all of our competitors' fans. We're confident that our fans, in an installed environment, are quieter than any comparable models on the market. Our decibel ratings have been independently tested by VIPAC Engineers & Scientists Ltd.

Frequency (pitch of the sound) is more important than overall noise (decibels). Most fans have a prominent motor ‘whine’ whereas our centrifugal fans have mostly airflow noise. Once installed, much of the airflow noise is eliminated by duct on either side of the fan, whereas motor whine still penetrates through building materials.

What is the difference between normal profile fans and low profile fans?

Normal Profile is our standard fan configuration. Normal Profile fans are round with a diameter of 342mm. Normal Profile fans are recommended for most installations.

Low Profile fans are available in 150mm duct size only for shallow installations where access is limited. Low Profile fans are oval with a width of 340mm and a height of 217mm. The smaller footprint means that air flow is reduced by about 10%, but they still provide exceptional performance as their shallow environments generally have less cubic volume to ventilate.

Can the fan speed be adjusted?

AC motors are single speed motors. They run at 100% all the time.

EC motors are variable speed motors. They have a 0-10V potentiometer mounted on them to adjust their speed precisely between 0% and 100%.

Why don't you like solar sub floor ventilation fans?

While we are firm believers in the benefits and need for solar (we have 21kW of it on our roof), unfortunately solar sub floor ventilation fans do not work.

Solar sub floor ventilation systems typically use very low wattage axial fans. Axial fans don't cope well with pressure, which means when ducting is installed airflow volume is severely reduced.

Solar sub floor fans are very noisy. On the numerous occasions we have installed them (against our recommendation) the biggest complaint received has been the noise!

Lastly, solar sub floor ventilation fans don't work well when it's cloudy, overcast, or raining - they often don't work at all on such days! Unfortunately, this is when you need them the most!

Why do you need mechanical sub floor ventilation?

Mechanical sub floor ventilation means there is a powered fan motor present to move air around. The alternative, passive sub floor ventilation, relies on free air movement through gaps and openings.

Passive sub floor ventilation includes any form of opening in the external walls of your sub floor area, such as weep holes, terracotta vents, wire mesh vents, and doors.

Passive sub floor ventilation is not effective if you are experiencing a mould and damp problem in your sub floor area. This is because it does not guarantee movement and exchange of air.

Cross-flow ventilation is nearly always impossible without mechanical subfloor ventilation. Air is lazy, so you can bet on it taking the path of least resistance. That’s why air always takes the easy way out as it moves through a sub floor space (assuming it even enters through restrictive passive vents in the first place). It’s much easier for air to pass through a large open section near the point of entry than to flow around multiple corners into small closed-off sections.

Having mechanical ventilation extracting stale air from these small closed-off sections creates cross-flow ventilation. This is because Air Out = Air In! Airflow is measured in cubic metres per hour (m3/h). For every cubic metre of stale air that gets drawn out from a space, 1 cubic metre of fresh air must get drawn in to the space. As the fans continually draw air out, fresh air enters through existing openings and works its way through the sub floor area to the point of extraction.

Why Premium Components and Proper Installation Matter

Fresh Ventilation supplies a range of efficient and technologically superior sub floor ventilation products. Our exclusive design is based on years of knowledge, experience and trialling competing products.

Not all components are equal!

System Design

Instead of using a single larger fan, we use smaller fans but more of them.

More fans allow greater coverage, better efficiency and more extraction points.

A single larger fan makes more noise, uses more power and requires longer duct runs to cover the same area as two smaller fans. This is inefficient and leads to uneven duct lengths and subsequently uneven air flow.

Our smaller fans use the same size ducting as our exhaust grilles and we allow one exhaust grille per fan. This allows air to be freely exhausted without a reduction in air flow due to pressure buildup.

Larger fans need reducers to reduce the duct size so that they can be connected to exhaust grilles. This results in a reduction of air flow due to resistance.

When comparing our systems against other systems with the same suggested coverage areas, our systems include more fans, more duct, more extraction points and more exhaust grilles.

Our systems are designed to properly ventilate your sub floor area.

We believe in doing the job right the first time.

Fans

Our 150mm AC and EC motor centrifugal fans have capacities of 540 m³/h and 735 m³/h respectively.

The single speed AC motor consumes 48 W and the variable speed EC motor consumes 49 W when running at a similar 580 m³/h capacity.

Our fans make less noise and use less power. Some larger fans use 193 W when operating and have less capacity than two of our smaller fans.

Our fans have a 5 year replacement warranty.

Timer

Our digital timer has a battery backup. It won't lose time and start running in the middle of the night.

Our digital timer can be programmed differently on different days of the week. This is ideal when you want different operation on the weekends.

Duct

Our duct is manufactured in Australia from two layers of high grade metallised polyester bonded together with fire rated resin encapsulating spring steel wire.

Our duct is not prone to tearing or unravelling like single layer competing products.

Exhaust Grilles

Our exhaust grilles are anodised aluminium, not plastic.

Our grilles are weather proof and have a rodent proof mesh behind them.

Our grilles are easy to install since they replace two standard bricks. The back box fills the hole left after removing two bricks and the anodised grille clips into the back box and covers any gaps with a 25mm flange. They don't require partial removal of bricks to create a round hole.

The back box fits snuggly in the wall, allowing duct to be connected securely so that there are no leaks, and does not require mortar to be redone after installation.

Our 150mm super quiet EC motor mixed flow fans have a 2 YEAR WARRANTY. All other fans and components have a 5 year warranty.

Negative Pressure, Positive Pressure or Balanced Pressure?

Installing the most suitable sub floor ventilation system in your home can help get rid of air pollutants that can harm your health and your family’s wellbeing. Fresh Ventilation offers efficient solutions that can eradicate stale, moist air in the sub floor area and replace it with cleaner, fresher and drier air. We have three different types of ducted sub floor ventilation systems that you can choose from.

All of our systems are available in any of the three pressure configurations – the components don’t change, the way they are installed determines the configuration.

Depending on how your sub floor ventilation fans are installed, they will either blow air into your sub floor area (positive pressure) or suck air out of your sub floor area (negative pressure). If you have two or more fans installed, it is possible for fans to both blow air in and suck air out of your sub floor area (balanced pressure).

Negative Pressure

Our most popular configuration. The logic behind a negative pressure system is that a greater quantity of stale air is sucked out of the sub floor area than the fresh air that is blown into it. The vacuum conditions created when stale air is continuously sucked out of the sub floor area will be filled by fresh air drawn in from outside.

Importantly, moisture and musty odours can be controlled since air is sucked out at a chosen location. However, the drying performance may be slightly slower than a positive pressure configuration.

Positive Pressure

A positive pressure system is the opposite of a negative pressure system. A greater quantity of fresh air is blown into the sub floor area using mechanical ventilation, which will as a result force the damp air out.

Positive pressure systems facilitate the drying up of damp or moist sub floor areas because dry air is constantly being blown over them. It can initially be more effective than trying to suck out moist air from damp surfaces. Caution needs to be taken to ensure that passive escape venting is sufficient for the damp air to leave the sub floor area to outside of the home, otherwise the dampness can end up rising into the home above.

Balanced Pressure

Your sub floor ventilation system can be configured as a balanced pressure system, but this needs to be carefully considered and understood before installation. Like any sub floor ventilation system, the key to an effective balanced pressure system is to ensure that it is installed properly.

One or more fans create a positive pressure by blowing dry and fresh air into the sub floor area. An equal amount of fans work using negative pressure to expel the same amount of stale and moist air from the sub floor area. It is balanced because the speed at which the air moves into and out of the sub floor area is the same.

Subfloor Ventilation System Sizing and Fan Selection

When determining which sub floor ventilation system is most suited to your home, it is important to consider:

- Fan configuration (negative, positive or balanced).

- Proper system sizing to ensure sufficient air flow and effective ventilation coverage.

- Construction materials of your home and its surroundings to ensure quiet and unobtrusive operation.

- Design effectiveness.

- Aesthetics.

- Price.

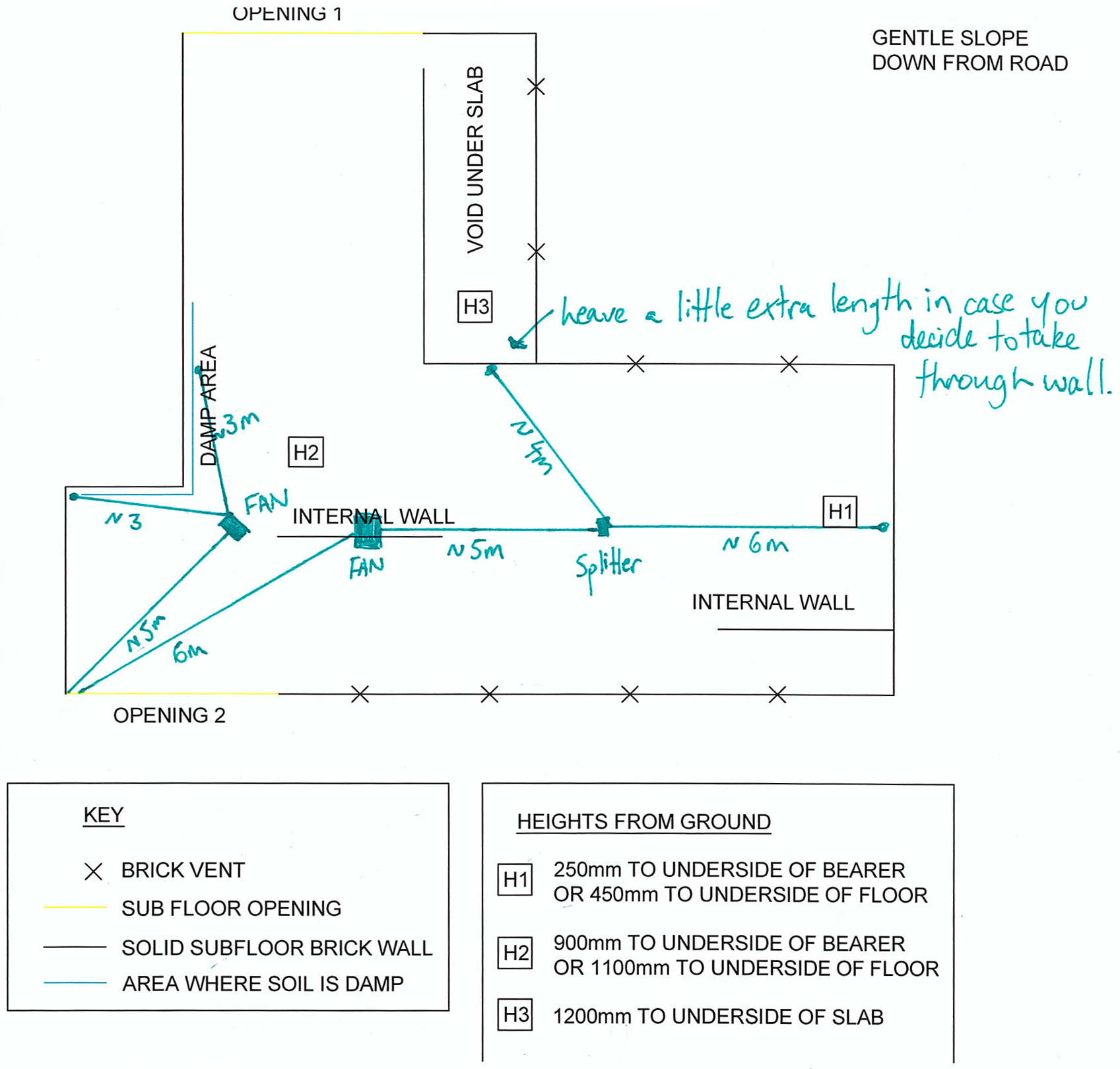

We recommend you contact us to arrange a free site inspection and quote. Alternatively, we are often able to provide accurate quotes on the spot based on information you provide via email/telephone and any diagrams/images you have available.

Buy Subfloor Ventilation Kits Online

All of our sub floor ventilation systems are available as DIY kits if you would like to install them yourself. We offer installation assistance and guidance by way of telephone conversations and personalised duct layouts with each kit.